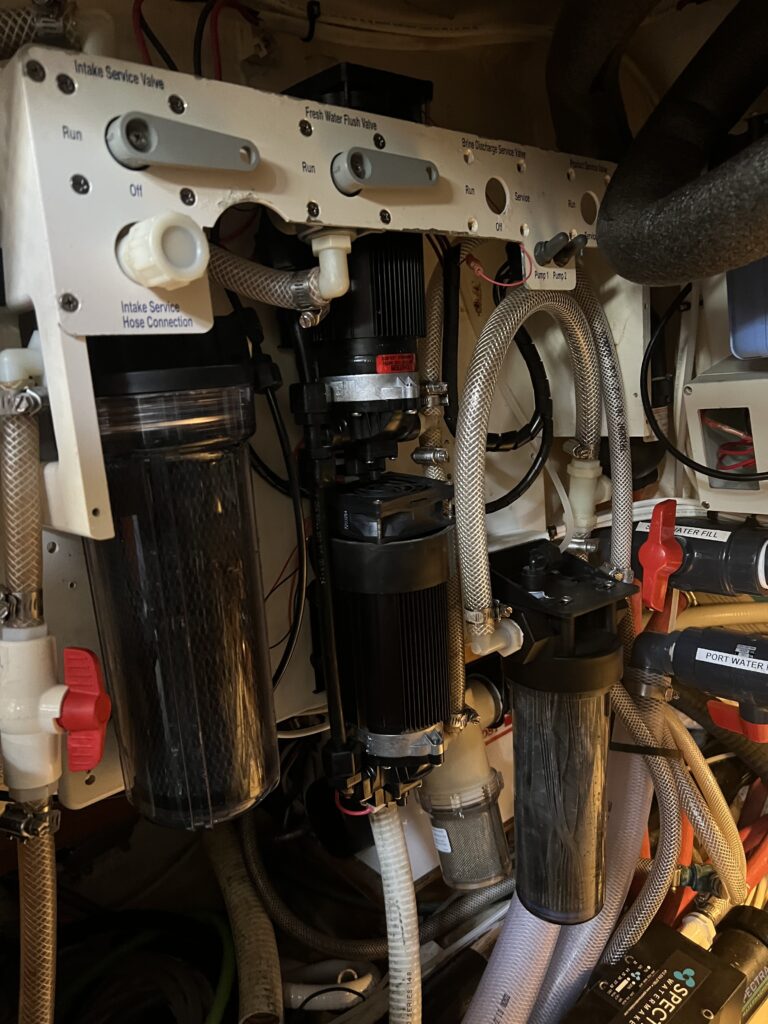

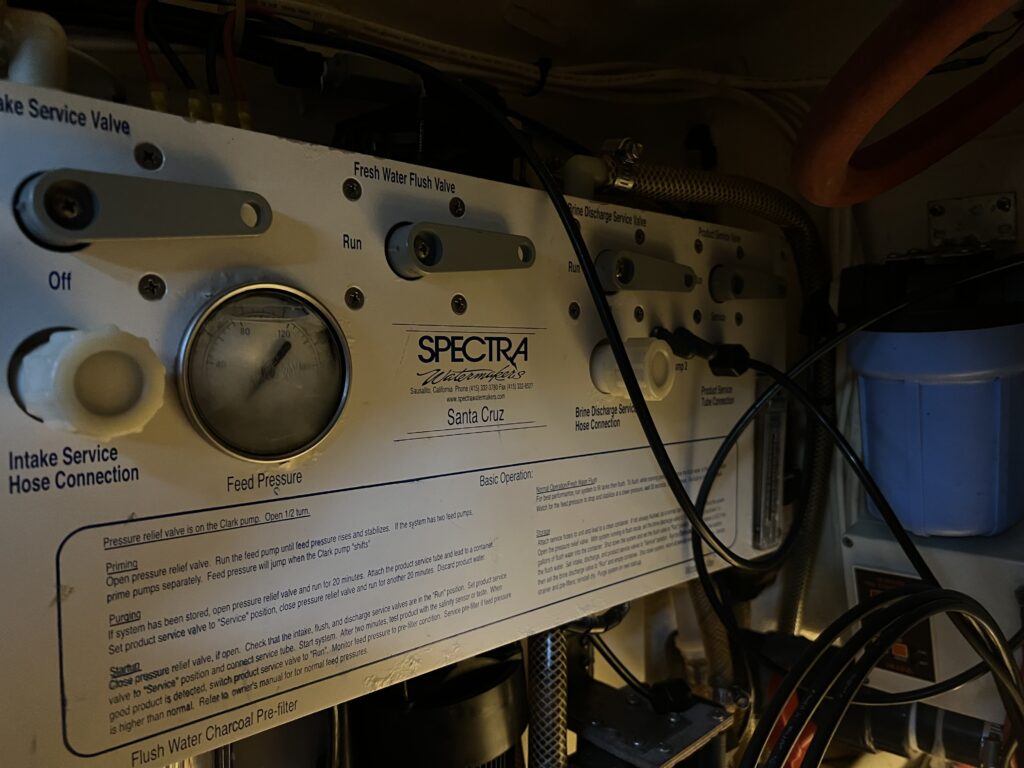

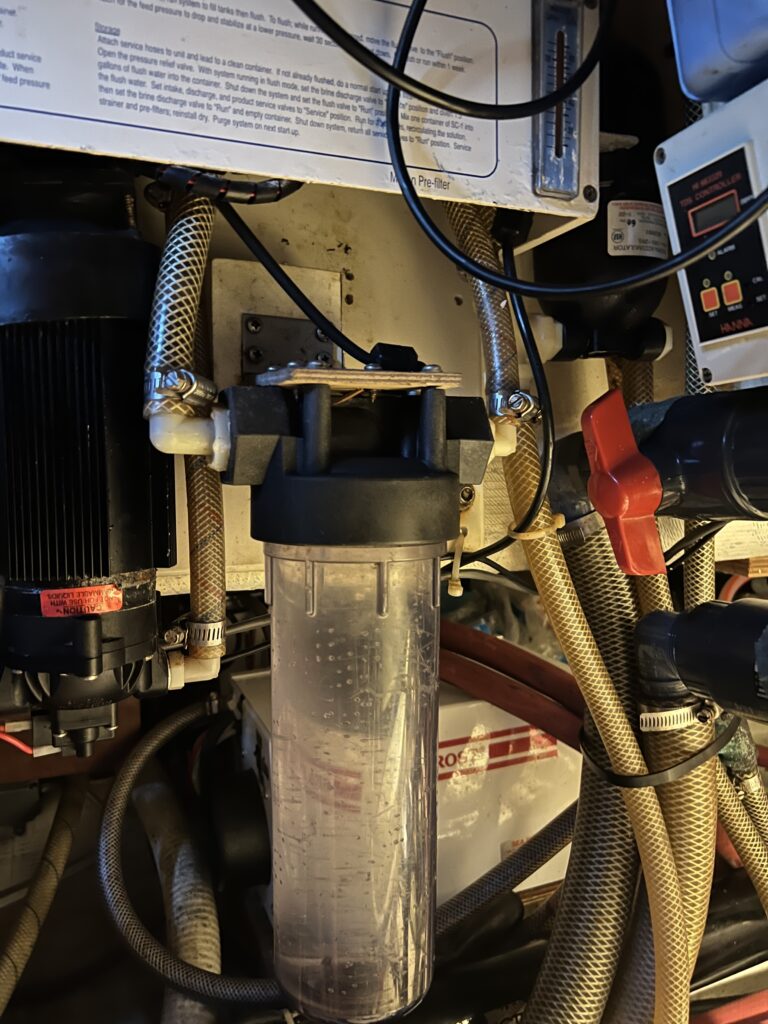

The boat came with an original Spectra Santa Cruz Water maker. Some modifications had been done, like a solenoid for kicking in the flushing of the system remotely and the pre filter had been dropped down out of the box, maybe for easier access to the housing.

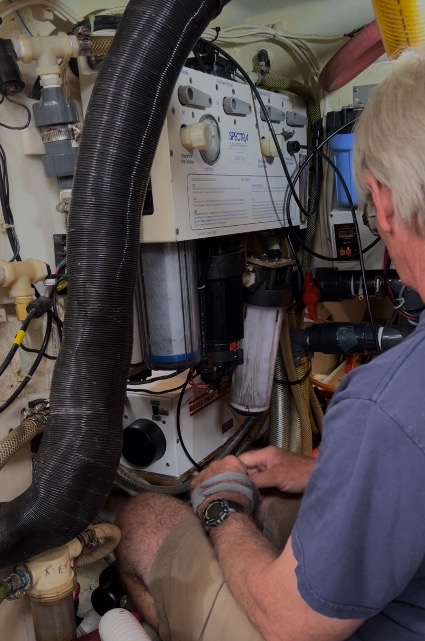

A cool thing about working on the boat in Seattle where it’s had so much work done before is that a lot of the same people are still in the industry. I wanted some training and help with the water maker so I didn’t mess anything up in getting it going again. Greg asked Dan with Emerald Harbor Marine to come down and help us get it going and it turns out Dan actually installed that water maker for the second owner of the boat and even helped sail it down the coast! Small world.

The Clark pump is the center of the system, I love understanding how it works and this diagram really helped that:

In our system, pre-filtered sea water enters the system through 2 water feed pumps which we can run together or one at a time. That lightly pressurized water goes into one or the other side of the larger cylinders on the Clark pump where it gets ultra pressurized and then into the membrane cylinder. A small percentage of the water molecules get pushed through the membrane (which looks like a bunch of tightly wound strands of fishing line) and into our water tanks. The rest of the water (now the brine) which is still pressurized flows back to the Clark pump and assists in driving the main cylinder, pretty cool way to harvest the same energy twice! Finally, that brine goes overboard through a shared exit with the fridge/freezer compressor water cooling out the transom. It’s a mess of hoses but it sounds pretty simple here, right?

Dan helped get the system back online, rebuilt our Clark pump so it’s functioning at 100% and will hopefully continue to do so, and made a few changes to the old Santa Cruz to make it more like the modern versions. He cut away the control panel so access to the pumps and filters is even easier and re-routed the controls and gauges for the pumps to a little panel in the galley. He also added a diverting valve near the sink so when we start up the system and water that’s been sitting in there a while is moving through it can divert right into the galley sink and we can test it there until it’s time to flip the valve to go into the tank. All that means we spend a little less time crunched up under the stairs where our 6’+ bodies don’t fit all that well, sweet. We’ve still spent a bunch of time in there chasing little leaks, our boat yoga game is strong.